Electronics Manufacturing

Advanced PCBA manufacturing services delivering precision, scalability, and reliability across all production volumes.

Altest has the solution for you! we have the latest equipment in advanced SMT technologies,Vapor Phase vacuum soldering, 3D X-Ray and Flying probe testing..

GET A QUICK QUOTE Medical

Medical

Aerospace & Defense

Aerospace & Defense

Industrial

Industrial

Advanced Capabilities.

Engineering expertise to build world-class electronic products.

Precision Manufacturing.

State-of-the-art SMT lines and automated inspection systems.

Modern Facility.

Newly upgraded equipment ensuring speed, consistency, and reliability.

End-to-end electronics manufacturing services engineered to support complex, high-reliability products from prototype to full-scale production.

Advanced PCBA manufacturing services delivering precision, scalability, and reliability across all production volumes.

High-reliability microelectronics solutions designed for size, weight, performance, and mission-critical applications.

Engineering expertise that accelerates design for manufacturability, cost optimization, and time-to-market.

Precision PCB fabrication supporting complex, high-density designs with strict quality and reliability requirements.

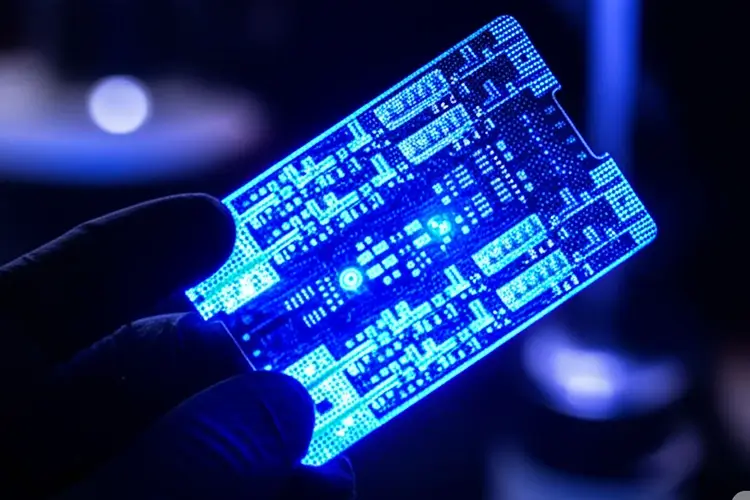

Comprehensive AOI, flying probe, functional testing, and 3D X-ray inspection to ensure product integrity.

Complete electromechanical and box build assembly under one roof, enabling faster integration and delivery.

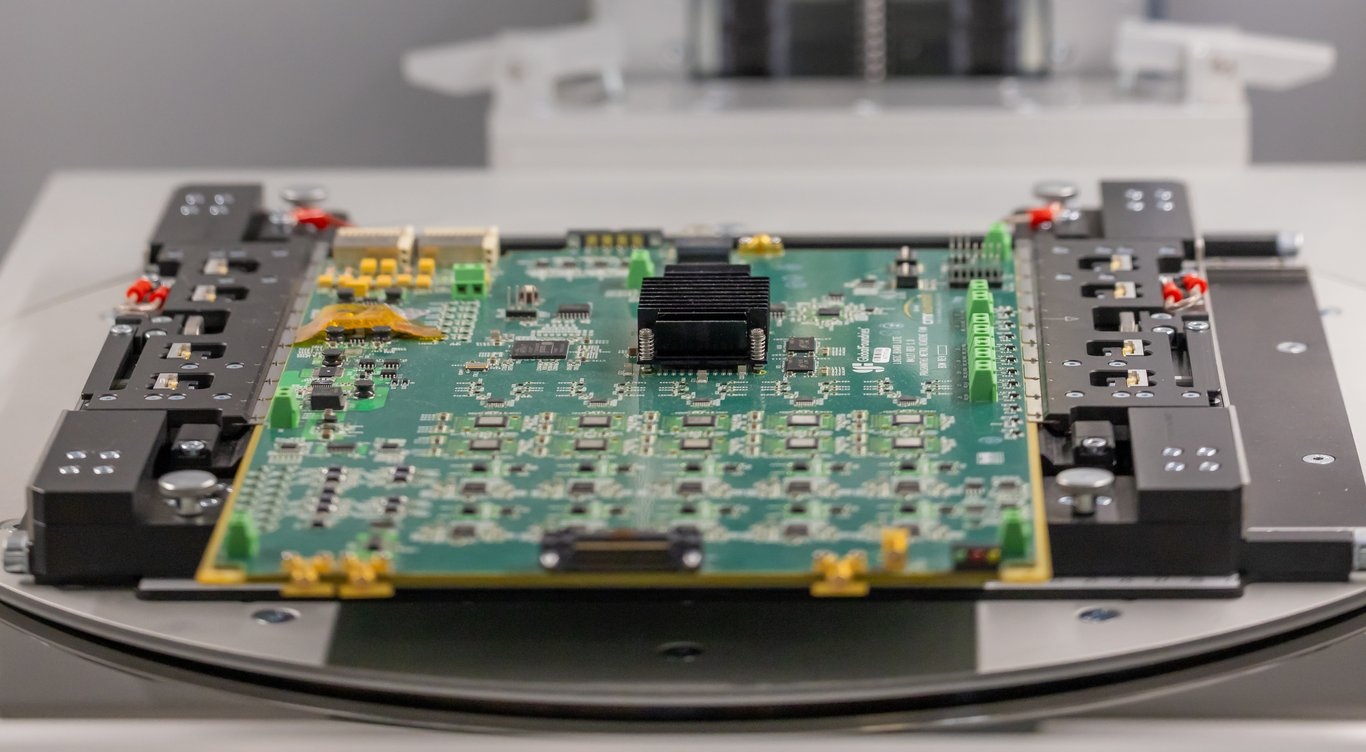

Explore our state-of-the-art inspection and assembly systems used for high-reliability PCB manufacturing.

Altest Corporation delivers high-reliability PCB assembly solutions across mission-critical industries, meeting IPC and global compliance standards.

Designed for defense applications requiring extreme durability, high precision, and long-term reliability.

Rugged PCB solutions for automation, power systems, and heavy-duty industrial electronics.

Automotive-grade PCB assemblies compliant with safety, vibration, and thermal requirements.

Flight-ready PCB assemblies meeting aerospace-grade quality and reliability standards.

Precision PCB manufacturing for life-critical medical devices and diagnostics equipment.

Altest Corporation is proud to operate a state of the art manufacturing facility equipped with the newest production technology. Several major systems in our factory are less than six months old, which ensures exceptional precision, consistency, and reliability for all builds.