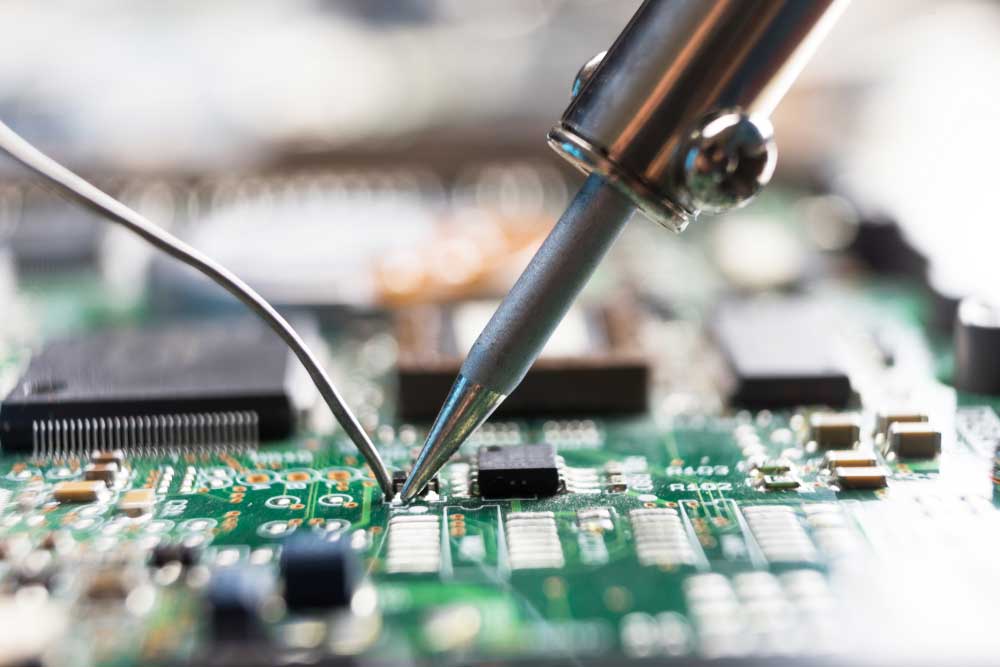

PCBAs REPAIR - REWORK

We fix defects, correct errors, or modify PCBAs after it has been manufactured. This is common in electronics production, as it’s rare for every unit to be perfect, especially when dealing with complex circuits, high-density designs, or issues that arise during soldering and component placement.

Common Repair and Rework Issues:

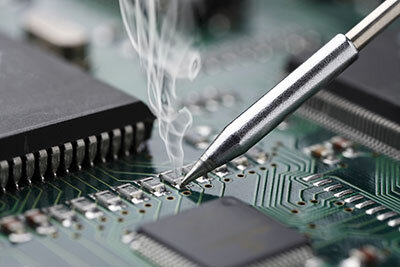

– Solder Bridges: Solder that has accidentally connected two adjacent pads, causing a short circuit. Fixed by desoldering and cleaning up the area.

– Cold Solder Joints: Joints that are improperly soldered, often resulting in a poor electrical connection. These can be fixed by reflowing the solder or adding more solder to the joint.

– Misplaced Components: Components placed in the wrong position or orientation. These are typically fixed by desoldering and repositioning the component.

– Component Failure: A component that has failed due to heat, manufacturing defects, or electrical stress. The failed component is removed and replaced with a new one.

– Damaged Pads/Traces: Traces that have been damaged or broken during assembly or testing. These are repaired using jumpers, conductive ink, or wire bonding.