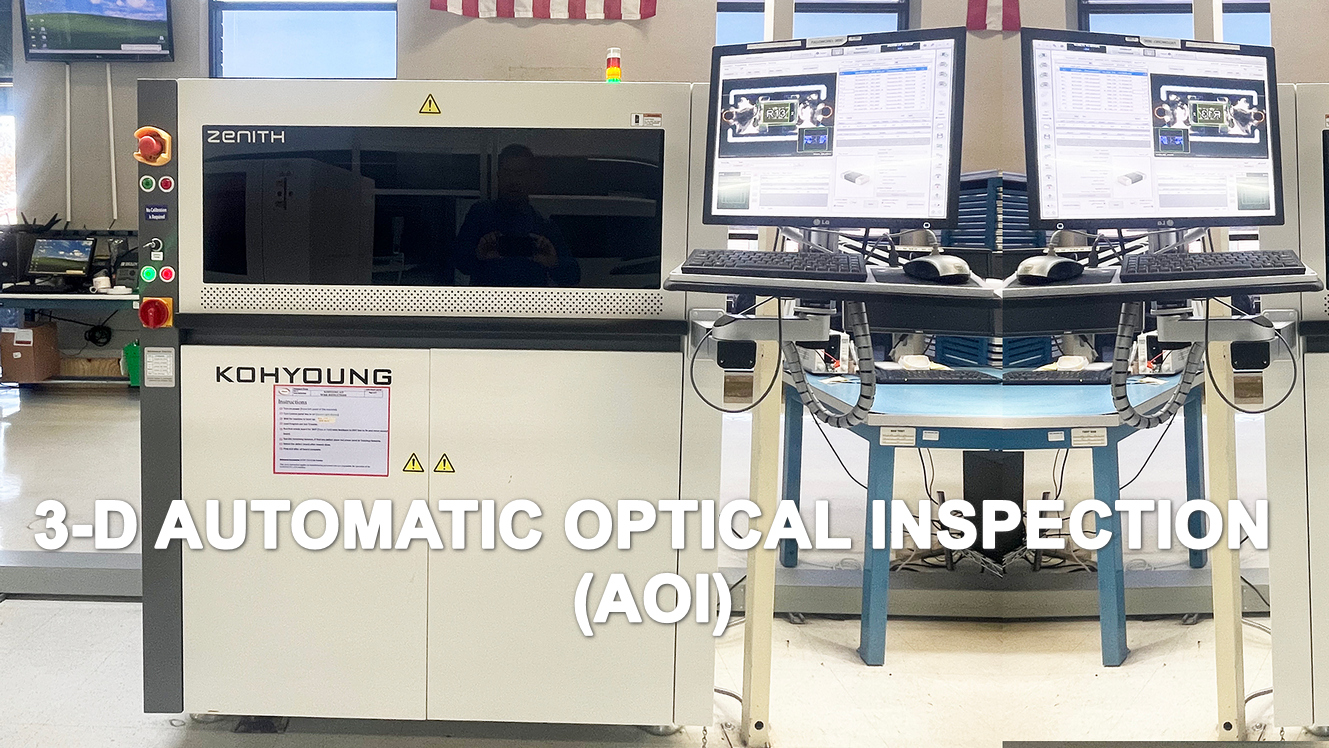

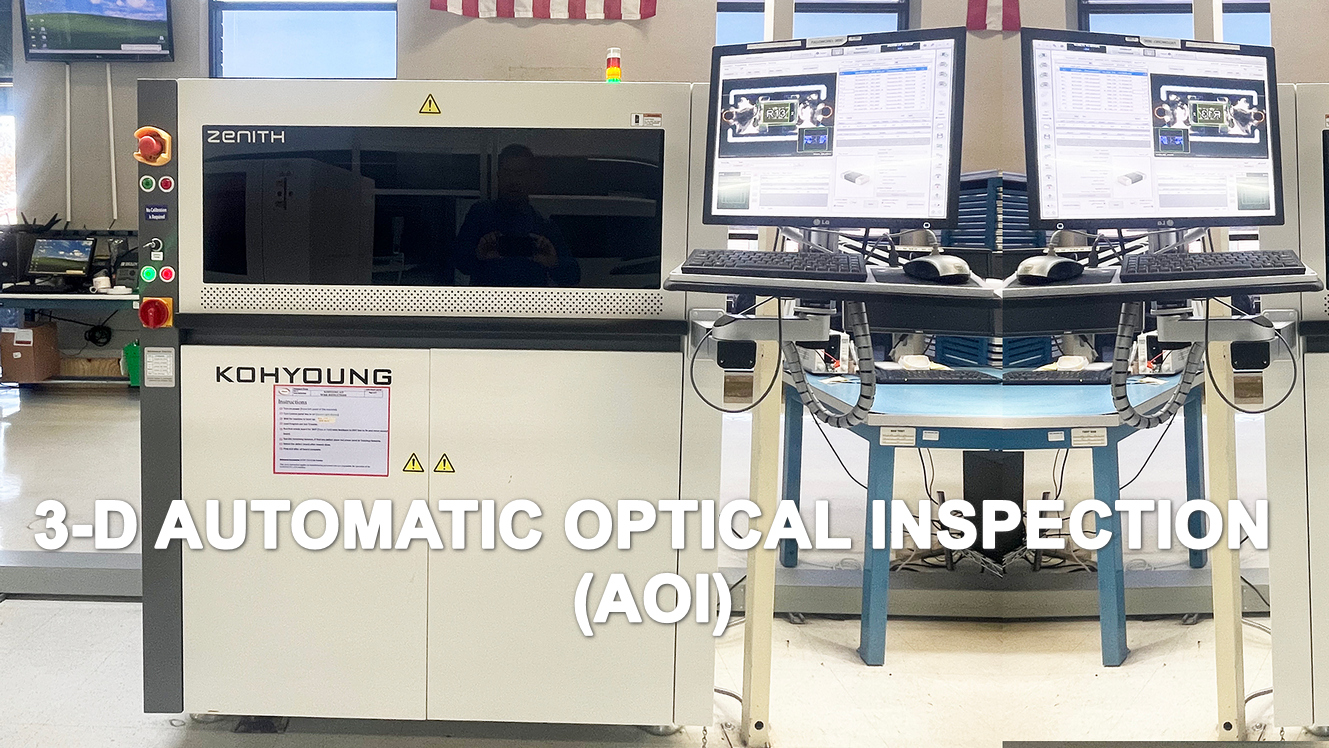

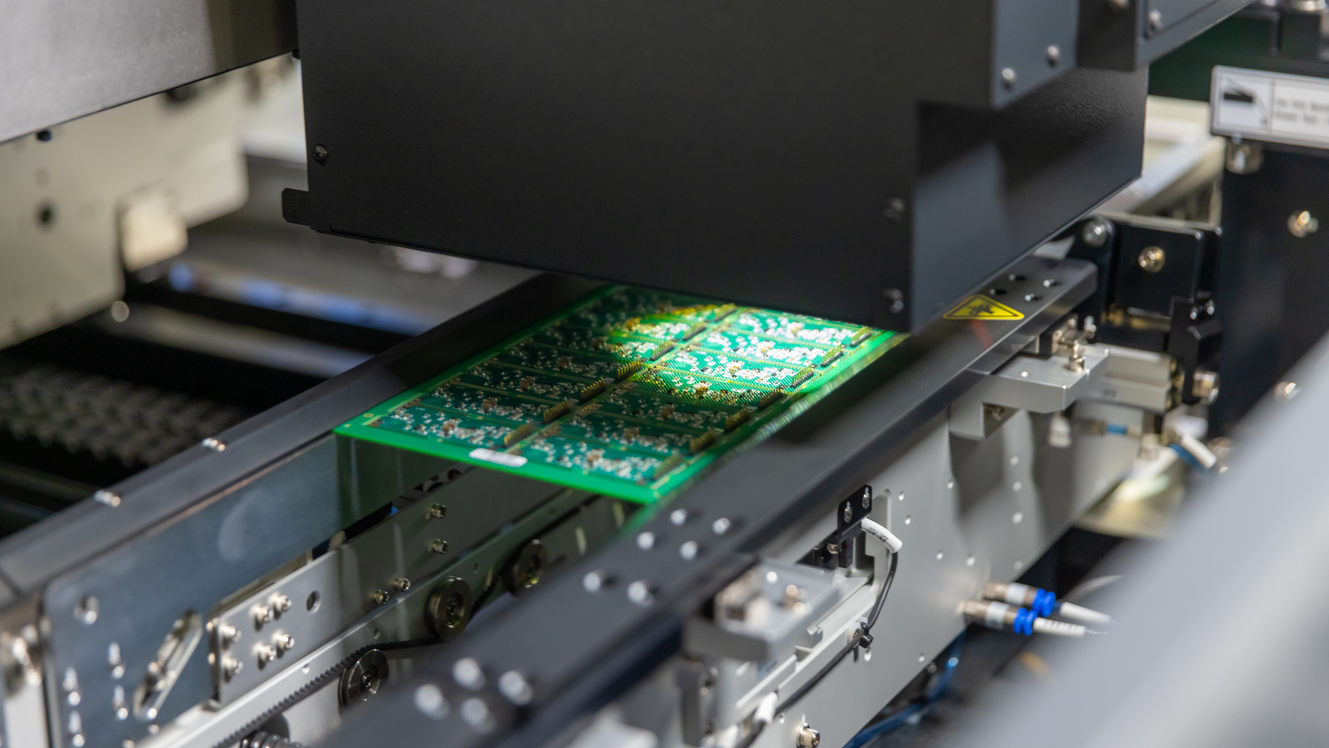

AOI (Automated Optical Inspection)

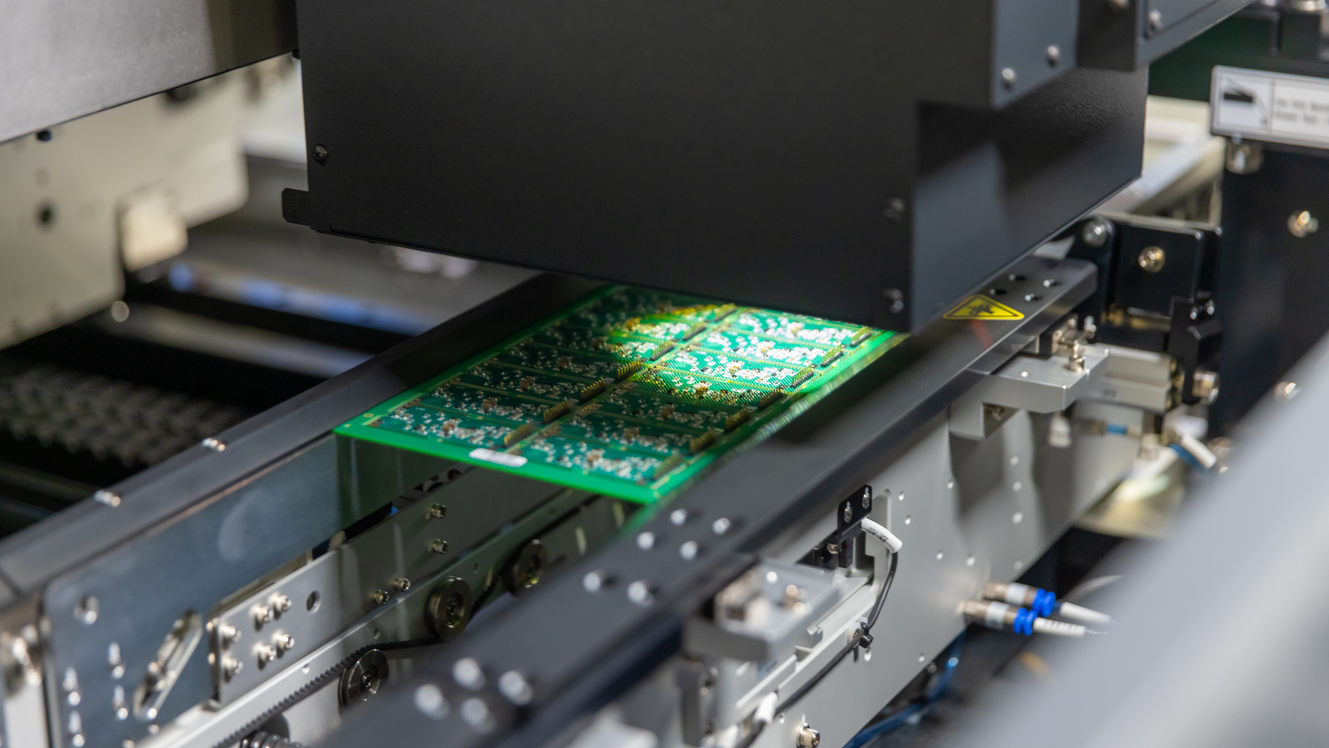

AOI: uses high-resolution cameras and computer algorithms to visually inspect the external surfaces of components and assemblies.

Advantages of AOI Testing

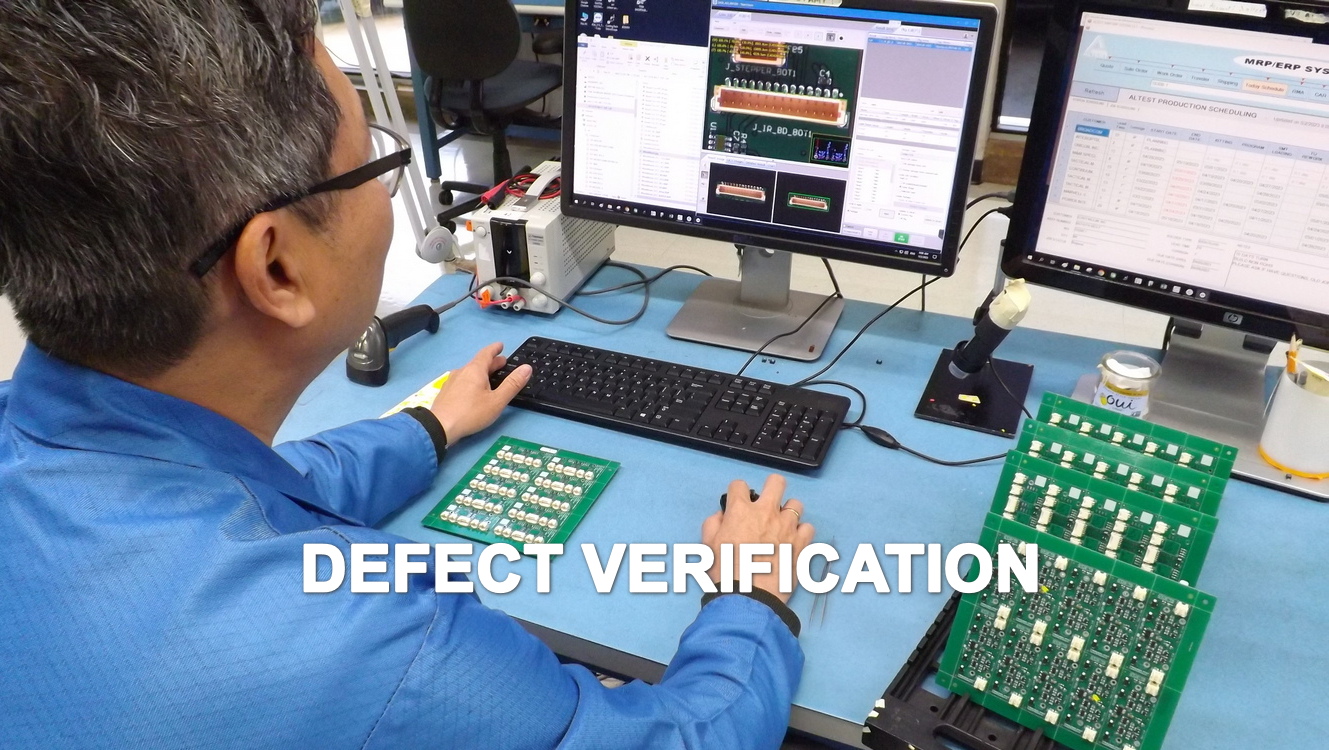

Speed: AOI is much faster than manual inspection, allowing for real-time feedback and quicker detection of defects, which is critical in high-volume manufacturing environments.

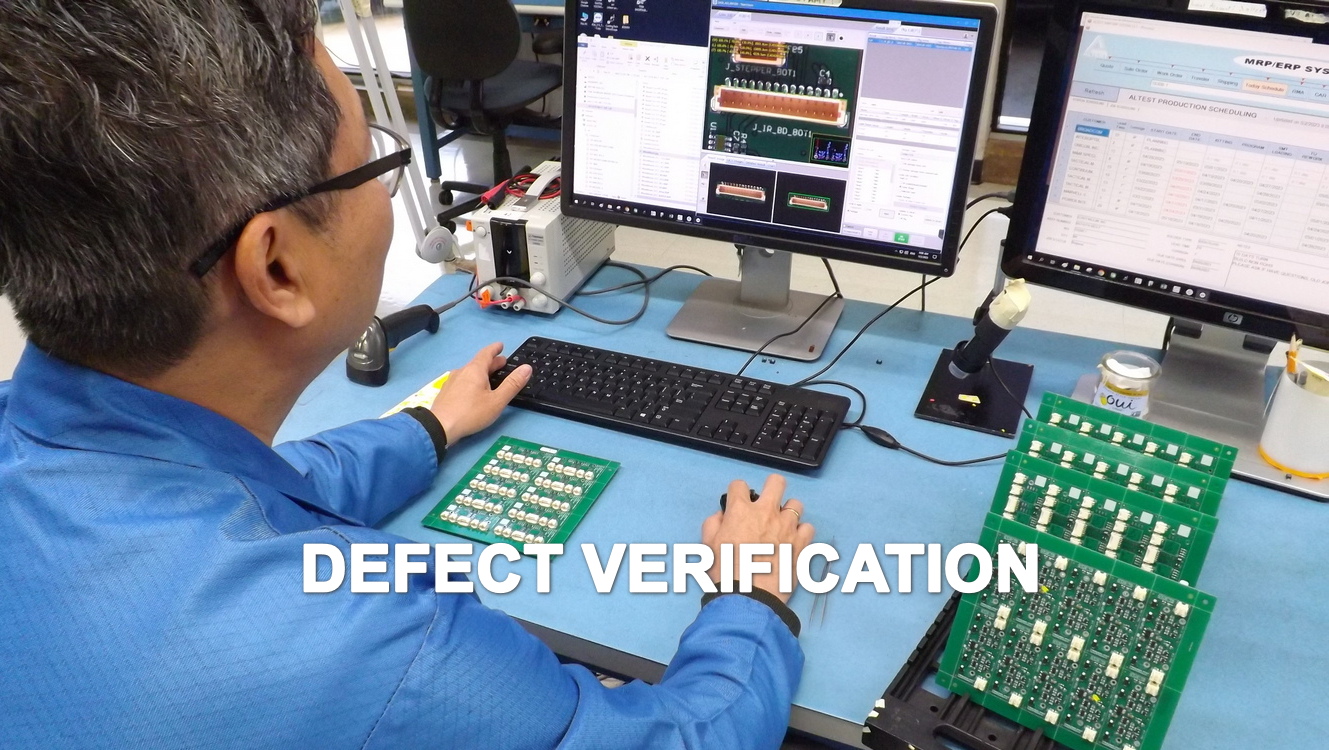

Consistency: The automated nature of AOI ensures that inspections are consistent across the entire production run, reducing human error and variability.

High Accuracy: AOI systems can detect minute defects with incredible accuracy, including very small soldering issues, surface imperfections, or minor misalignments that would be hard for the human eye to detect.

Cost-Effective: While AOI systems may require an initial investment in equipment, they can significantly reduce labor costs associated with manual inspection, and they can operate 24/7 without fatigue.

Non-Destructive: AOI is