BGA REWORK

BGA Assembly Services

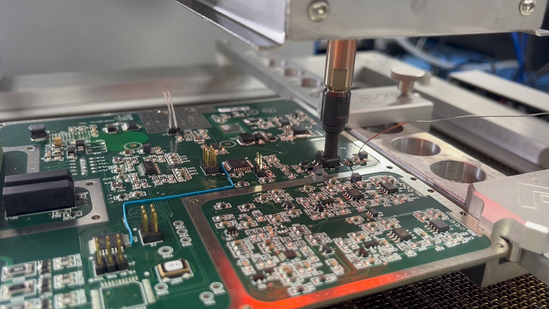

– Soldering and Placement: Accurate placement of BGA components on PCBs is essential due to the small size and tight tolerances of the solder balls. Advanced equipment, such as pick-and-place machines, ensures precise alignment and attachment.

– Reflow Soldering: After positioning, reflow ovens are used to heat the board, causing the solder balls to melt and form reliable electrical connections. This step is crucial for achieving uniform solder joints.

BGA Rework and Repair Services

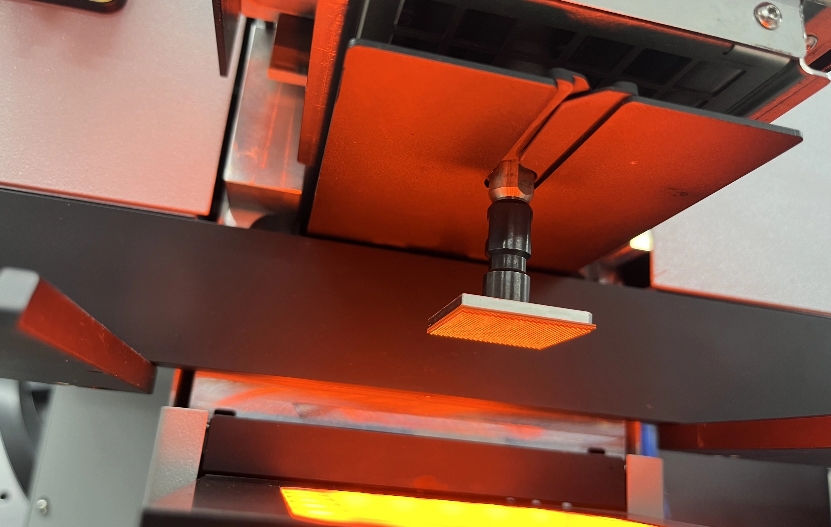

– Component Removal and Replacement: When BGA components become faulty or need updating, specialized rework equipment can desolder and remove the component without damaging the PCB. After removal, a new BGA component can be soldered in place.

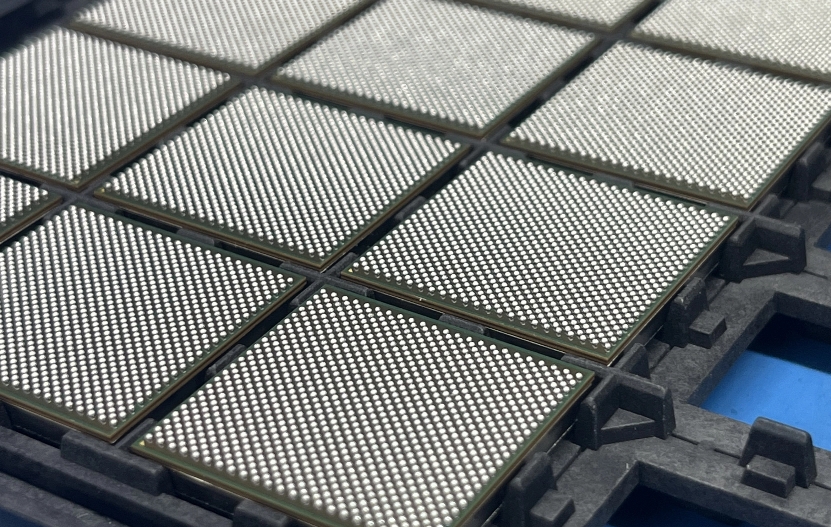

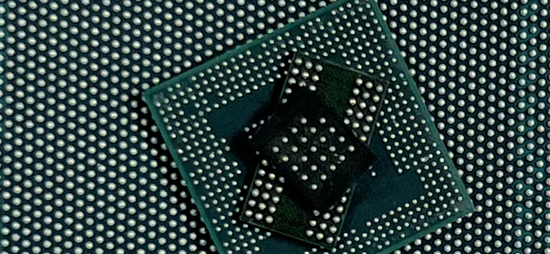

Reballing Services: If solder balls become damaged or require replacement, reballing services allow for removing the old solder balls and attaching new ones. This can be more cost-effective than replacing the entire component, especially for high-value ICs.

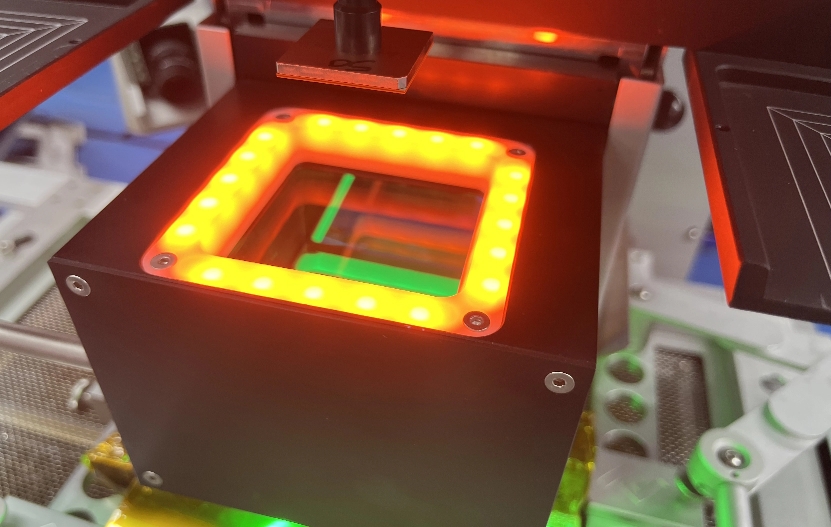

Inspection and Testing Services