Microwave & RF PCB

RF and Microwave PCBs are considered some of the most advanced Circuit boards in the industry. Even Signals beyond 1Ghz require a fair share of caution and effort for designing. Some of the advantages are

Microwave and RF PCB ?

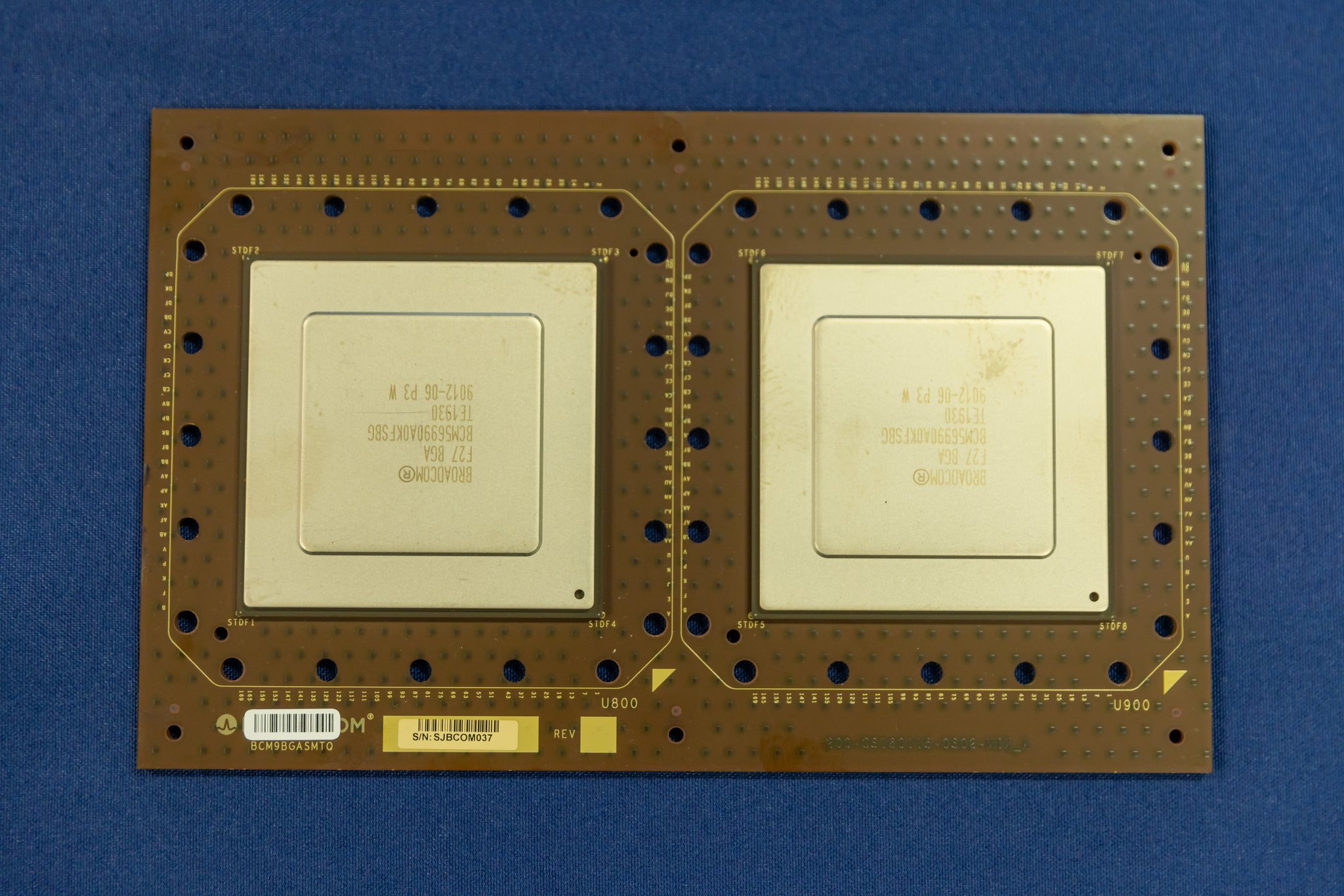

RF Microwave PCB Design & Fabrication : RF microwave PCBs are typically built using advanced composites with very specific characteristics for dielectric constant (Er), loss tangent, and co-efficient of thermal expansion (CTE).

Quick Turn Capabilities for RF and Microwave PCBs:

If you have a job that needs to be done in a hurry, look no further than us. We have impressive quick turn PCB capabilities — including top engineers and state-of-the-art equipment

How do I start with RF PCB design?

Firstly we need to know the function and the usage of your applications. Secondly, we need to design a diagram. Thirdly we generate Gerber files for PCB fabrication and a BOM list for PCB assembly. Finally, a thorough analysis of RF PCB material is a must, and it will help to get our devices with high quality and competitive pricing.

-

What is a Microwave PCB?

The main difference between RF circuit boards and Microwave PCBs is in the radio frequency in which they operate. Microwave PCBs are classified as any RF circuit board operating above 2GHz.

-

Microwave PCB and RF Circuits–Common Problems and Solutions

RF circuit boards, and Microwave PCBs, are especially difficult to design compared to traditional PCB layouts. This is due to the problems that could arise in receiving or transmitting the radio signals. Some of the main problems are noise sensitivity, and tighter impedance tolerances

-

RF Board Applications

RF boards have a multitude of different applications, including wireless technologies, smart phones, sensors, robotics and security. With the advent of new technologies that are pushing the limits of electronics, the demand for RF boards is on the rise.

Industries We Serve:

Why Choose Our Microwave & RF PCBs?

Precision Engineering

Our PCBs are engineered for optimal performance, ensuring minimal signal loss and maximum reliability. Benefit from precise impedance control and stable signal integrity, crucial for high-frequency applications.

Customized Solutions

We understand that every project is unique. Our team works closely with you to deliver customized PCB solutions, meeting specific design requirements and industry standards.

Rapid Prototyping & Production

Speed up your development cycle with our rapid prototyping services. Quickly move from design to production while maintaining high-quality standards.

Type of RF Printed Circuit Boards

-

Rigid RF PCBs

- Flexible RF PCBs

- Rigid-Flex RF PCBs

- RF Antenna PCBs

Rigid RF PCBs are the ones produced by high-speed radio frequency materials. It can be a single layer, double layers and multilayers. Most time it is multilayers since there are impedances embedded in RF PCBs. For multi-layer RF PCBs, the substrate material is sandwiched together with copper traces in multiple layers

They utilize flexible substrate materials like polyimide or polyester for the formation of the board. They can be used to fit into compact and irregular spaces accordingly. It finds applications in areas where mechanical flexibility is an important requirement.

The combination of rigid and flexible substrate material in a single board is why it is called rigid-flex RF PCBs. They have the features of both rigid and flex PCBs combined together and offer some design complexity by maintaining the signal integrity of the RF board.

They are specifically built for applications involving RF antennas. Here the PCB itself may serve as the antenna structure. They are designed in a way to optimize antenna performance in terms of gain,