In the world of medical devices, precision and reliability are paramount. Every gadget, from life-saving monitors to intricate diagnostic tools, relies on its brain—the Printed Circuit Board (PCB). This step-by-step guide will walk you through the entire PCB board assembly process, providing valuable insights and tips along the way. Our focus is on making the process accessible and straightforward for medical device manufacturers and electronics engineers.

Understanding the Importance of PCBs in Medical Devices

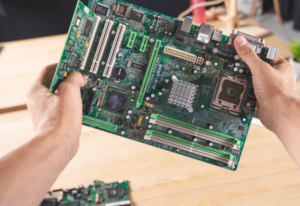

Printed Circuit Boards (PCBs) form the backbone of modern medical devices. They are responsible for ensuring that the various electronic components communicate effectively, allowing the device to function as intended. The stakes are high in the medical field, where any malfunction can have serious consequences. Therefore, understanding the PCB assembly process is crucial for manufacturers and engineers aiming to produce reliable and durable medical equipment.

Initial Design Considerations

Before the first component is placed on a board, careful planning is essential. Start by considering the specific requirements of the medical device. What functions will the PCB need to support? Are there particular size constraints? Is there a need for specific materials to withstand environmental factors like humidity or exposure to chemicals?

Design software, such as Altium Designer or Eagle, can be incredibly useful at this stage. These tools allow you to create detailed schematics and layouts. It’s also vital to consider the manufacturability of the design. Complex designs may lead to higher costs and longer production times, which can be critical factors in the medical device industry.

Selecting the Right Components

Choosing the correct components for your PCB is another crucial step. Each part must meet the medical device’s specific requirements, including performance, reliability, and safety standards. Components should be sourced from reputable suppliers to ensure quality and compliance with industry standards.

For medical devices, components often need to be biocompatible and resistant to sterilization processes. This consideration can affect your choice of materials and components significantly. Make sure to consult with suppliers who specialize in medical-grade components to make informed decisions.

Prototyping and Testing

Prototyping is where the initial concept begins to take physical shape. A prototype allows you to test the PCB in real-world scenarios, identifying any potential issues before mass production. Rapid prototyping methods, such as 3D printing, can be particularly beneficial here, allowing for quick iterations and adjustments.

Once the prototype is ready, rigorous testing is essential. This phase includes functional testing, stress testing, and ensuring that the board meets all regulatory requirements. In the medical field, compliance with standards like ISO 13485 and IEC 60601 is mandatory. Detailed documentation of the testing process will be necessary for regulatory approval.

PCB Fabrication Process

The fabrication process involves several steps, beginning with the preparation of the substrate material. For medical devices, materials like FR-4 (a flame-retardant material) are commonly used due to their durability and reliability. The substrate is then coated with a layer of copper, which will form the circuitry.

Next, the design is transferred onto the board using a photolithographic process. This step involves applying a photosensitive film to the copper layer and exposing it to ultraviolet light through a mask of the circuit design. The exposed areas are then etched away, leaving behind the circuit pattern.

After etching, the board goes through a series of cleaning and inspection steps to ensure accuracy. Any defects at this stage can lead to significant issues later in the assembly process, so thorough inspection is critical.

Component Placement and Soldering

Once the PCB is fabricated, it’s time to place the components onto the board. Surface Mount Technology (SMT) is commonly used for this purpose, allowing for precise placement of components directly onto the surface of the board. Automated pick-and-place machines can place thousands of components per hour with high accuracy.

Common abbreviations

| SMp term | Expanded form |

|---|---|

| SMD | Surface-mount devices (active, passive and electromechanical components) |

| SMT | Surface-mount technology (assembling and mounting technology) |

| SMA | Surface-mount assembly (module assembled with SMT) |

| SMC | Surface-mount components (components for SMT) |

| SMP | Surface-mount packages (SMD case forms) |

| SME | Surface-mount equipment (SMT assembling machines) |

After placement, the components need to be soldered to secure them in place. Reflow soldering is the most commonly used method, where the board is passed through an oven to melt solder paste and form electrical connections. For through-hole components, wave soldering might be used, where the board is passed over a wave of molten solder.

Quality Control and Inspection

Quality control is a continuous process throughout PCB assembly, but it becomes especially critical after soldering. Automated Optical Inspection (AOI) systems can be used to check for soldering defects, component misalignment, and other common issues. X-ray inspection might also be employed, particularly for complex boards with multiple layers and hidden connections.

Manual inspection is also necessary, especially for boards used in medical devices. Skilled technicians can identify issues that automated systems might miss. Comprehensive testing, including functional tests and stress tests, ensures that the PCB meets all design specifications and regulatory requirements.

Final PCB Assembly and Integration

The final assembly involves integrating the PCB into the medical device. This step often includes connecting the PCB to other components, such as sensors, displays, and power supplies. Careful attention to detail is essential to avoid damaging the board or other components during this process.

Once assembled, the device undergoes another round of testing to ensure that all components work together seamlessly. This phase includes software integration testing if the device is controlled by embedded software. Ensuring that the software and hardware work together without issues is crucial for the device’s overall functionality.

Ensuring Compliance and Certification

Medical devices are subject to strict regulatory standards, and compliance is non-negotiable. The PCB assembly process must adhere to standards like IPC-A-610, which sets the acceptability criteria for electronic assemblies. Additionally, the entire device must comply with medical standards such as ISO 13485 for quality management systems and IEC 60601 for electrical safety.

Documentation is a significant part of the compliance process. Detailed records of the design, manufacturing, and testing processes must be maintained and submitted to regulatory bodies for certification. Working with experienced consultants can help streamline this process and ensure that all requirements are met.

Maintenance and Troubleshooting

Once the medical device is in use, ongoing maintenance is necessary to ensure its continued reliability. This includes regular inspections and testing to identify any potential issues before they become critical. A proactive maintenance schedule can extend the device’s lifespan and ensure it continues to meet regulatory standards.

Troubleshooting is also an essential skill. Understanding common issues that can arise in PCBs, such as thermal stress, component failure, and connection issues, allows for quick identification and resolution of problems. Having a well-documented troubleshooting guide can assist technicians in maintaining the device’s functionality.

The Role of Automation in PCB Assembly

Automation plays a significant role in modern PCB assembly, enhancing both efficiency and accuracy. Automated pick-and-place machines, reflow ovens, and inspection systems reduce the risk of human error and increase production speed. For medical device manufacturers, these benefits translate into higher quality products and faster time-to-market.

Investing in automation technology can provide a competitive edge. While the initial cost may be high, the long-term benefits of improved consistency, reduced labor costs, and increased production capacity are significant. Keeping up with the latest advancements in automation technology ensures that your manufacturing process remains cutting-edge.

Future Trends in PCB Technology

The field of PCB technology is continuously evolving, with new trends and advancements emerging regularly. Innovations such as flexible PCBs, which can bend and twist without breaking, are becoming increasingly popular in medical devices. These flexible boards can be integrated into wearable devices and implants, opening new possibilities for patient care.

Another trend is the use of advanced materials, such as ceramics and high-frequency laminates, which offer improved performance and durability. These materials can withstand harsh conditions and provide better signal integrity, making them ideal for medical applications.

Conclusion and Next Steps

The assembly of PCBs for medical devices is a complex but rewarding process. From initial design considerations to final compliance and certification, each step requires careful attention to detail and adherence to strict standards. By understanding and following these steps, medical device manufacturers and electronics engineers can produce reliable, high-quality products that meet the needs of healthcare professionals and patients.

If you’re looking to integrate PCB assembly into your medical device manufacturing process, consider partnering with experts who can provide guidance and support. Their experience and knowledge can help streamline the process, ensuring that your devices meet all regulatory requirements and deliver exceptional performance.

2 Responses